Traditional optical glass fibers are poor in flexibility when their diameters are not small enough. Further, they are relatively fragile and are apt to be broken by impact. Furthermore, they are heavy, because their specific gravity is comparatively large. In addition, the optical fibers themselves as well as their connectors are expensive. Due to these drawbacks, attempt has been made to replace glass materials with plastic materials.

What is Plastic Optical Fiber?

Plastic optical fiber (POF) (or Polymer optical fibre) is an optical fiber that is made out of polymer. Similar to glass optical fiber, POF transmits light (for illumination or data) through the core of the fiber. Its chief advantage over the glass product, other aspect being equal, is its robustness under bending and stretching.

POF has been called the "consumer" optical fiber because the fiber and associated optical links, connectors, and installation are all inexpensive.

Due to the attenuation and distortion characteristics of PMMA fibers, they are commonly used for low-speed, short-distance (up to 100 meters) applications in digital home appliances, home networks, industrial networks (PROFIBUS, PROFINET), and car networks (MOST). The perfluorinated polymer fibers are commonly used for much higher-speed applications such as data center wiring and building LAN wiring. Polymer optical fibers can be used for remote sensing and multiplexing due to their low cost and high resistance.

Core 96%, 1.0 mm Plastic Optical Fiber, (POF), typically uses PMMA (acrylic), a general-purpose resin as the core material, and fluorinated polymers for the cladding material. The optical wavelength of this fiber is 650nm, compatible with standard off the shelf components.

In large-diameter fibers, 96 percent of the cross-section is the core that facilitates the transmission of light. Although quartz fiber is widely used for infrastructures, POF has been called the "consumer" optical fiber. This is due to the fact that costs of POF, associated optical links, connectors and installation costs are low.

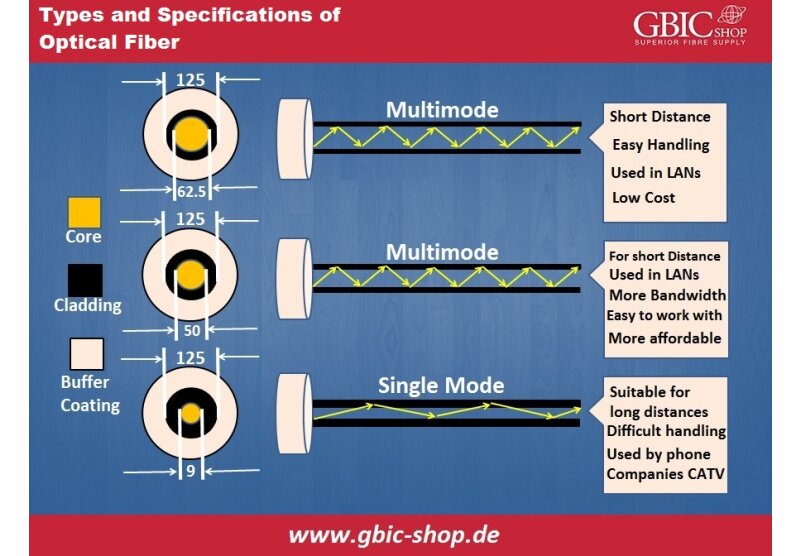

The advantages with plastic materials are numerous. For instance, the resulting optical fibers are light, tough and flexible so that their diameters and numerical apertures can be made large. Further, for instance, their handling is easy and can be readily connected to light emitting and/or accepting elements. In general, a plastic optical fiber comprises a core made of a plastic material having a larger refractive index and a good optical transmission and a cladding made of a plastic material having a smaller refractive index and a high transparency. In this structure, light is transmitted by reflection at the interface between the coreand the cladding.

Plastic optical fibers strongly differ from glass fibers in various respects:

Many POF have their loss minimum at visible wavelengths, or in the near infrared (at < 1.3 μm) in case of perfluorinated polymers. For comparison, silica fibers have their loss minimum at > 1.5 μm, and some other glasses even at much longer wavelengths.

A typical POF has high propagation losses of e.g. 50 or 100 dB/km, whereas silica fibers can achieve a few dB/m (multimode fibers) or even well below 1 dB/km (single-mode fibers). Therefore, data transmission with POF is limited to much shorter distances.

POF are usually multimode fibers with a large core (diameter of the order of 1 mm) and a high numerical aperture (e.g. 0.4), thus supporting a large number of guided modes. This is beneficial when light-emitting diodes are used as data transmitters. In the same way as for glass fibers, intermodal dispersion can be minimized by using graded-index profile designs.

POF appear not to be suitable for single-mode guidance.

POF are mechanically more robust and flexible. Their multimode guidance with a large core and high NA greatly relaxes the tolerances for connectors, so that simple plastic parts can be used and no sophisticated training is required. Due to these reasons, and not cheaper materials, POF allow for substantial cost savings in various applications. POF cables can be thinner and more lightweight than mechanically well protected glass fiber cables.

English

English

Deutsch

Deutsch

Espaniol

Espaniol