The prerequisites for manufacturing a good optical fiber patch cords are represented by the choice of good quality components that make the final product a trusted brand for optical patch cords. The traditional production process of fiber optic patch cable can be divided into three parts: assembly of fiber optic cable and connectors, end face polishing, inspection & testing. Features of good connector design: Low insertion loss, High return loss, (low amounts of reflection at the interface), Ease of installation, Low cost, Reliability - more than 500 times mating, Low environmental sensitivity, Ease of use.

A fiber patch cords is made of two major parts:

Optical connector and fiber optic cable.

Optical fiber connectors are used to join optical fibers where a connect/disconnect capability is required. Due to the polishing and tuning procedures that may be incorporated into optical connector manufacturing, connectors are generally assembled onto optical fiber in a supplier’s manufacturing facility. A fiber-optic connector is basically a rigid cylindrical barrel surrounded by a sleeve that holds the barrel in its mating socket. The mating mechanism can be push and click, turn and latch (bayonet), or screw-in (threaded). A typical connector is installed by preparing the fiber end and inserting it into the rear of the connector body. Quick-set adhesive is usually used to hold the fiber securely, and a strain relief is secured to the rear. Once the adhesive sets, the fibers end is polished to a mirror finish. Various polish profiles are used, depending on the type of fiber and the application. For single-mode fiber, fiber ends are typically polished with a slight curvature that makes the mated connectors touch only at their cores. This is called a physical contact (PC) polish. The curved surface may be polished at an angle, to make an angled physical contact" (APC) connection. Such connections have higher loss than PC connections, but greatly reduced back reflection, because light that reflects from the angled surface leaks out of the fiber core. The resulting signal strength loss is called gap loss. APC fiber ends have low back reflection even when disconnected.

Optical connector types may be:

- LC fiber optic patch cable

- FC fiber optic patch cable

- SC fiber optic patch cable

- ST fiber optic patch cable

- MU fiber optic patch cable

- MTRJ fiber optic patch cords

- E2000 fiber optic patch cables

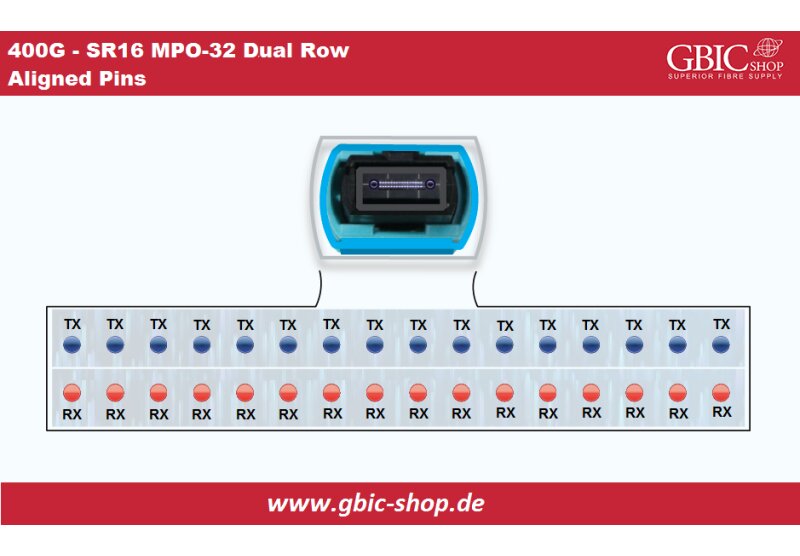

- MPO fiber optic patch cords

- ESCON fiber optic patch cords

Fiber optic cable types used for patch cords may be:

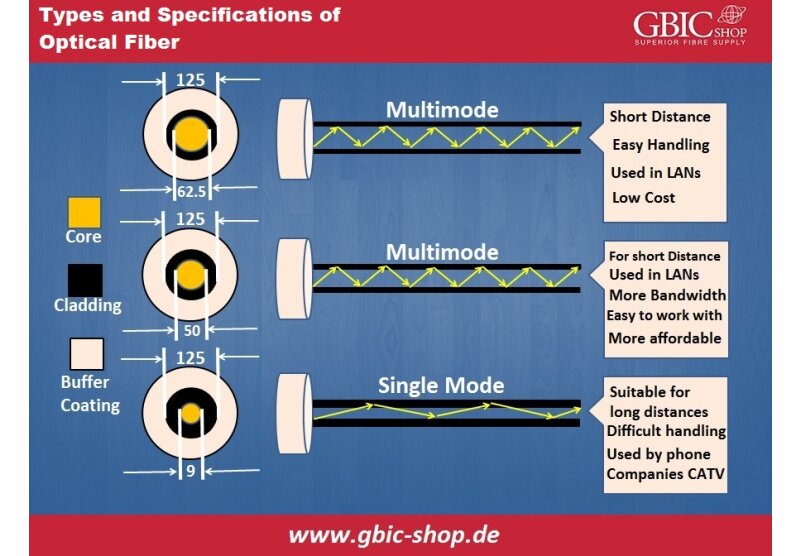

Single mode fiber optic cable: Generally in yellow color and used for long transmission distance;

Multimode fiber optic cable: Generally the multimode patch cable are orange or gray and are used for short distance transmission.

Optical fibers are composed primarily of silicon dioxide (SiO 2 ), though minute amounts of other chemicals are often added. Because the purity and chemical composition of the glass used in optical fibers determine the most important characteristic of a fiber — degree of attenuation—research now focuses on developing glasses with the highest possible purity.

Both the core and the cladding of an optical fiber are made of highly purified silica glass. An optical fiber is manufactured from silicon dioxide by either of two methods. The first, the crucible method, in which powdered silica is melted, produces fatter, multimode fibers suitable for short-distance transmission of many light wave signals. The second, the vapor deposition process, creates a solid cylinder of core and cladding material that is then heated and drawn into a thinner, single-mode fiber for long-distance communication.

Fiber optic cable jackets may be:

PVC: Non-Flame Retardant;

LSZH : Low smoke zero halogen, Flame Retardant.

Espaniol

Espaniol

Deutsch

Deutsch

English

English