Formerly, optical fiber connectors were unmanageable and not easy to utilize. With producers’ uniformity and facilitation of optical fiber connectors, the optical fiber connectors have become more appropriate for more delicate presentations. As they have become uncomplicated, this quality has caused the enhancement in the utilization of fiber optic programming. This article will discuss the market of present-day fiber-optic joiners and a comprehensive presentation of fiber optic joiners.

A SHORT ASSESSMENT OF THE OPTIC FIBER CONNECTOR MARKET:

In current years, the worldwide marketplace has been extending the acceptance of optical fiber technology. Generally, the use of fiber optic wires is increasing rapidly to take the place of copper wires, and this has an excellent impression on the market of fiber optic joiners. The bar chart given below from Grand View Research signifies the advancement of optical fiber joiner kinds such as MTP, LC, SC fiber optic joiners in modern years.

It is simple to realize from the diagram that the development of specific five generally utilized optical fiber joiners has a strong tendency. LC joiners still preserve the big fiber-optic joiner market in the coming years. The necessity for MPO/MTP joiners is also increasing in recent times, which shows that the MPO/MTP joiners can be likely to hold plenty of market share.

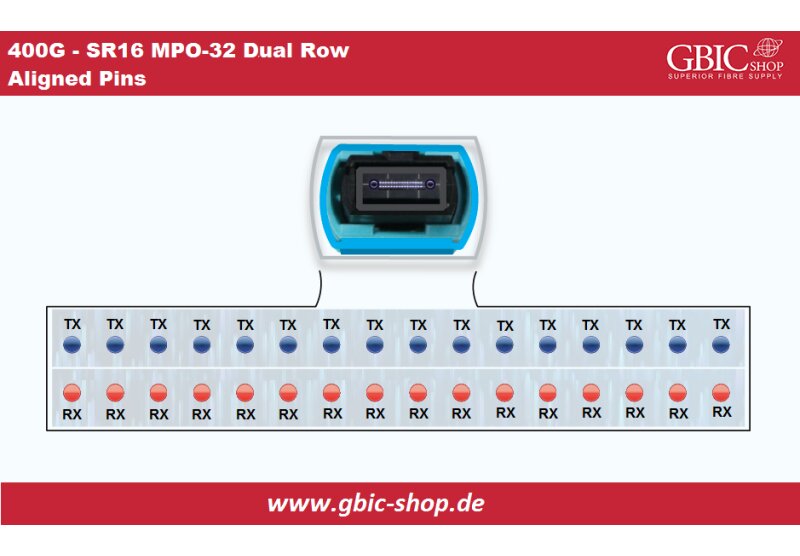

To conclude, the whole developing tendency has shown the continuous requirement for fiber optic joiners. Moreover, the market is observing the progress of fiber joiners. Top-quality and high-density connectors such as LC joiners continue to be the best option for various customers. Furthermore, the multi-optical fiber joiners such as MPO/MTP joiners and Rosenberger Q-RMC joiners can get more support because of the demand for high-level bandwidth, 5G implementations, and 100G/200G/400G system utilizations. We may predict that optical joiners that can present uncomplicated installation, reduced fiber loss, and excellent presentation will progress in fiber-optic connections due to the increasing requirement for effective cabling and wire management.

ARCHIVES OF OPTICAL FIBER CONNECTOR:A DESCRIPTION OF OPTICAL FIBER CONNECTOR:

Fiber optic joiner is a segment to finish the end of optical fiber wire and allows faster link and detachment over fiber splicing. It automatically combines and adjusts the fiber optic cores to let the light proceed proficiently. That’s why optical fiber joiners significantly affect the transmission dependability of fiber optic and the presentation of the structure. Generally speaking, the highest-quality fiber optic joiners will suffer the loss of minimal light because of the reflection or disorder of the optical fibers.

WHAT ARE THE STANDARDS FOR OPTICAL FIBER CONNECTORS?

Regarding Optical components, optical fiber joiners follow various standards in telecom wiring or the department of electrical engineering. The chart given below shows the portion of measures presented by optical fiber joiners.

DESIGN OF OPTICAL FIBER CONNECTOR:

We have five main and significant elements for designing a fiber optic joiner: the sub-assembly figure, the joiner housing, the fiber optic ferrule, fiber optical wire, and stress buster boots. An SC joiner can be taken as an example to describe the formation of an optical fiber joiner.

- FIBER OPTIC FERRULE:

The SC optical connector is made for a long circular diameter ferrule of 2.5mm formulated by metal or ceramic. A perfect hole of 124um-127um is perforated in the middle of the ferrule, where the bare fiber is placed straightly and generally connected by adhesive or epoxy. At the ending of the ferrule is the end of the wire, wherein it is usually smoothly polished.

- SUB-ASSEMBLY FIGURE:

The ferrule is gathered in the sub-assembly figure of SC that possesses techniques to maintain the fiber and wire in place. The ending of the ferrule is away from the sub-assembly figure to join some other connector within a mating sleeve.

- JOINER HOUSING:

After that, the optical fiber joiner housing will protect the joiner sub-assembly figure, giving the techniques for breaking within a mating sleeve and keeping the joiner in place.

- FIBER CABLE:

Fiber wire and strength joiner are crumped upon the joiner sub-assembly figure with a crumple eyelet, growing the force of the automatic control of the joiner and securing the fiber internally simultaneously.

- STRESS BUSTER BOOT:

Stress buster boot protects the link between the joiner figure and fiber wire to prevent mechanical harm. Designs of stress buster boot are distinct for 900um tight-buffered optical fiber wire and 1.6 millimeters to 3-millimeter optical fiber wire.

IMPORTANT FEATURES OF OPTICAL FIBER CONNECTORS:

The main features of the Optical Fiber connectors are compatibility, dependability, reproducibility, installation times, etc.

- Optical qualities: Return loss and insertion loss are two primary specifications for fiber optic qualities. If the value of insertion loss is lower, it is satisfactory. Generally, a competent joiner has to maintain the value of insertion loss under 0.5dB. Conversely, a more significant return loss will show a good presentation of the joiner. The standard value of the joiner’s return loss has not to be lower than 25Db and not lower than 45Db because of the polishing procedure. The recommendation of Return Loss and Insertion Loss for Fiber Optic Joiners will describe the following two specifications of fiber joiner for your understanding.

- Compatibility and Reproducibility: Optical fiber joiners are global pliable devices, and the optical fiber joiner of a similar kind may be utilized in any fusion and may utilize

- High Dependability: Outer plant implementations can demand that fiber joiners should be based underground or outside walls. High dependability fiber optic joiners are required in these severe conditions to ensure untroubled fiber optic transmission.

- Usage Rate: Generally, the usage rate may be plugged in more than 1000 times. That’s why a fiber optic joiner that is uncomplicated to utilize will support customers to preserve a lot of insertion time and enhance working capability.

KINDS OF FIBER OPTICAL CONNECTORS:

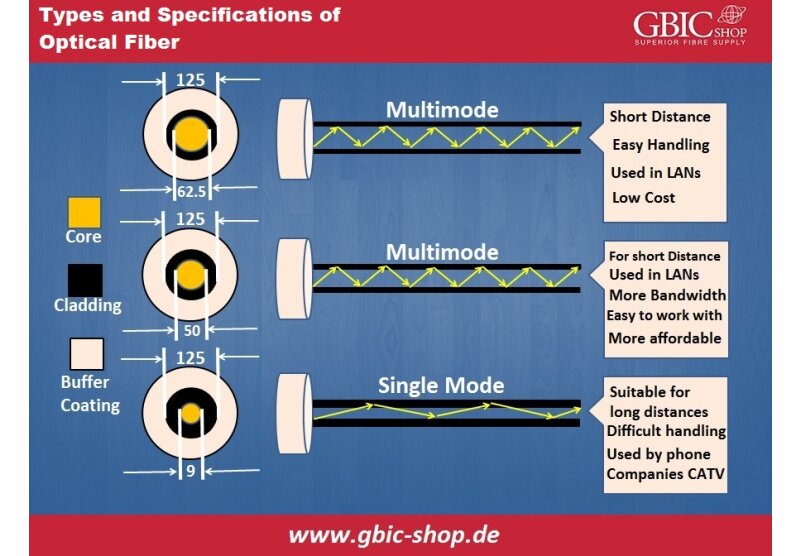

Optical fiber connectors can be divided into various kinds. By the surface and pin of the joiner, they are divided into UPC, APC, and PC. In accordance with mixed communication media, optical fiber joiners are divided into multimode and single-mode fiber joiners. Multimode optical fiber joiners have been launched in the market. Nevertheless, a small number shows the best part of the market, such as SC, LC, ST, FC, and MPO/MTP joiners.

The types of optical joiners shown above are generally optical fiber joiners that, for connection, demand an adapter panel which is broadly utilized in telecom rooms, data centers, cloud storage systems, server farms, etc. Nevertheless, two fresh and strong commercial joiners from Rosenberg, which are named NEX10 and Q-RMC optical fiber joiners, make use of the design Push-Pull Quick Lock for uncomplicated insertion. The joiners NEX10 and Q-RMC were created for use in severe conditions and are suggested to be used in commercial sites, mobile communication, 5G base station, minefields, etc.

COUPLING LOSS OF FIBER OPTIC CONNECTOR:

The light attached to the collecting fiber’s core will pass on, whereas the remaining light is not transferred via splice. Moreover, it is released out of optical fiber. Preferably, the damage can be reduced in case the two optical fiber cores are similar and completely paralleled, the splices or joiners are rightly finished, and there is no presence of dirt.

Unluckily, the joiner and fiber are both susceptible to manufacturing tolerances that generate lower than accurate adjustment.

Various components produce splice and connector loss. To take an example, ending gaps will have an impact on return loss and installation loss. That’s why fiber optic joiners will accept a lot of polishing methods to protect the physical connection of optical fiber edges to decrease back reflection. Moreover, light with a huge NA (numerical aperture) will be greatly susceptible to end gap and angularity from an optical fiber. Therefore communication from an optical fiber of huge NA to a little NA would be a loss greater than the reverse. That is to say, making a connection of big fibers to small ones ends in considerable dropping, not only because of the small core size the minor NA of many small core optical fibers is also a reason.

OPTICAL FIBER CONNECTOR IMPLEMENTATIONS:

Basically, the optical fiber wire with optical fiber joiners is mostly utilized in telecommunication departments from small-scale offices to data centers of large-scale. The given diagram indicates that telecommunication is considered for the biggest market share in respect of expenditures. Moreover, growing requirements of 5G network, 100/200 and 400G strong Speed Communication and demand will also be inspired by the cloud-based implementations. There still remains a continuous increase in worldwide requirements arising out of the Burgeoning IT manufacturing concerning the accessibility of cost-effective and higher network substructures.

Moreover, military & aerospace, medical application, and the oil & gas segments are composed to observe significant developing rates because of the increasing acceptance of POF (Plastic Optical Fiber) and multimode fiber over these implementation segments. For example, military forces use fiber optic joiner technology for various sea, air, ground, and space solicitations like in avionics examining apparatus modules and ground comfort techniques in armed aircraft.\

FREQUENTLY ASKED QUESTIONS:

- Should I select a 126um or 125.5um ferrule hole for 125um optical fiber? What is the distinction?

ANS: It suggested that the size of 126um ferrule hole is better for 125um SMF, and a few 125.5um ferrules are achievable for crucial alignment circumstances. Nevertheless, a ferrule hole of 126um enables a little epoxy bond about the optical fiber for fiber installation beyond any breakage.

- How are optical fiber Connectors examined?

ANS: Generally speaking, the examination is of two types: factory testing and field testing. Factory test use of profiling sure the accuracy of the complete, polished structure of the optical fiber joiners. Infield testing, a specific portable fiber microscope can be used for observing blemishes and dirt and some other particular tests to check the specifications.

- How to select a genuine optical fiber Connector?

ANS: Fiber patch wires could be bought with various configurations (SC-L, SC-SC, etc.). The requirements of your optical fiber connector will be determined by the kind of apparatus you are placing. For the fiber optic equipment connection, there are patch wire configurations and many adapters that we can use.

- Regarding the cleanliness of the Optical fiber Connector, what is the perfect time and method?

ANS: When the optic joiner is not terminated, there has to be a covering on it to secure the ending of the ferrule from any dirt. Before examining and connecting, highly recommended to purify the ends wipes moisture with isopropyl spirit. There are specific swabs, wipes, and detergents for sanitation to follow the purification instructions of the manufacturer is a sensible choice.

Espaniol

Espaniol

Deutsch

Deutsch

English

English