The fiber installation professionals may recall the days when they had these painstaking days of installing and connecting numbers of fibers. As this digital era started to take a speedy flight from 2000, and there was an exponent rise in the data centers, the cable designers and the installers were given the task of installing and managing hundreds of single- and 2-fiber connector solutions in a day. As this task was getting into their nerves and required a lot of maintenance with also elaborative space to accumulate the wires and connectors, they had to find the solution to the same. So, to solve the issues they were facing, at the very right time, the multi-fiber push-on (MPO) was brought into the market. At the heart of MPO is the mechanical transfer (MT) ferrule technology, which is the basis of MPO connectors. The coming of MPO reduced the required time and efforts that were needed to deploy network technologies.

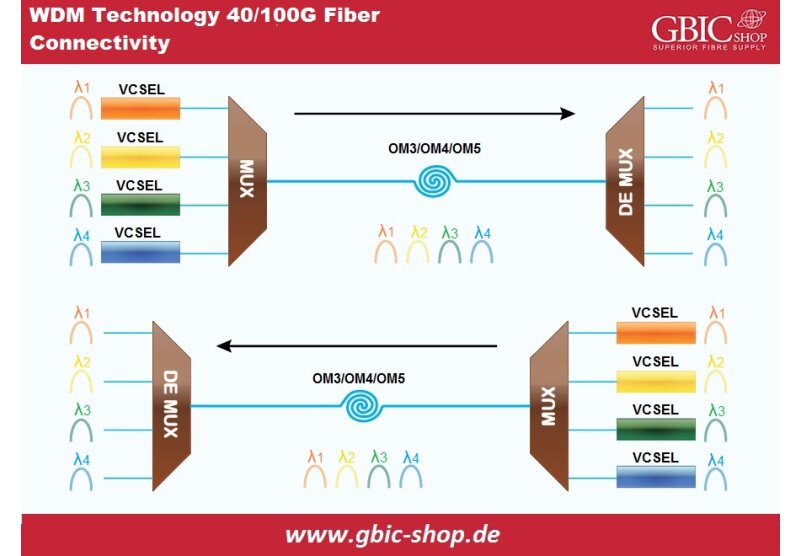

Consecutively, even after the MPO was introduced, the demand for the increased bandwidth was in progress too. With that, the industry started to move towards the networks and cabling with higher fiber densities, or you can say, the multilane highway of data transmission. Now, this today is known as optical transmission using multiple fibers or parallel optics.

However, as there are a lot of lanes used in the parallel optics, the number of fibers that were used to transfer the data back and forth, to maintain the same, a high-density interconnector was required too. So, the deployment of the multilane and to keep up the polarity was getting difficult. Thus, to address the challenge mentioned in the latter sentence, the Multi-fiber Termination Push-on (MTP) was brought into the market. The MTP with its bulkhead-mounted coupler made the pair and un-pair of the high-density MT ferrule format easier and reliable.

What Is MTP Connector, & How Is It Different From MPO

The MTP dominates the market of high-end performance marketplace. The places that require high-density network applications such as data centers, broadcast communications, and industrial places, use these connectors. The MTP connector, a registered trademark of US Conec, is the acronym of the Multi-fiber Push-on. Now, This MTP in the layman language or in the industry on a daily basis is interchangeably used with the MPO. Though the MTP connectors are entirely compliant with the MPO and are compatible with the MPO connectors, too, they are not actually the same. The MPO, which is a standardized interface type, the MTP can be said as the high-performance MPO, with multiple engineered product enhancements, that enhances the optical and mechanical performances.

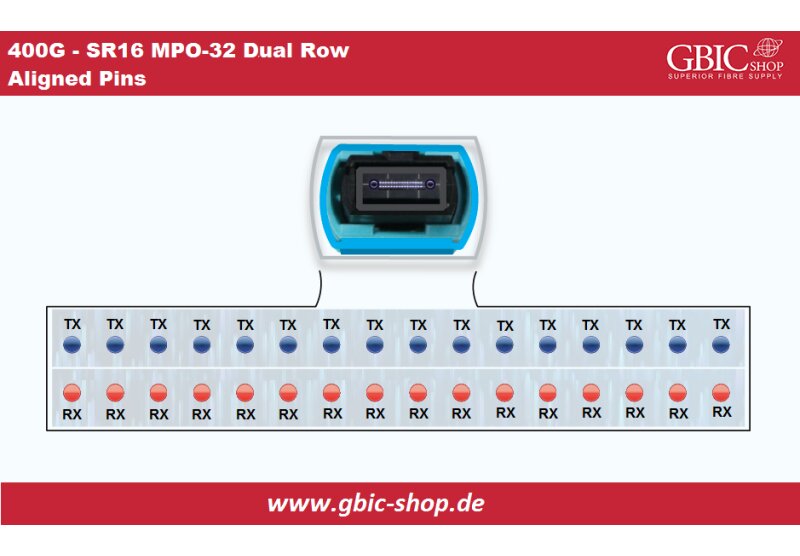

With the help of the MTP connector, quick connections can be established. The work that was done in the entire day, cutting that long time’s work, now the cabling can be done in just a few hours. The MTP can provide a quick connection for the 8 to 12 fibers at a time with very minimum tools or with some pre-terminated plug-and-play cable. However, they have the capability to establish the connection for up to 72 optical fibers, in which people opt to get 12 or 24 fibers, often.

Now, joining different cables, these connectors can become MTP trunk cables, like 24 fiber MTP to MTP trunk cable or MTP -LC harness cables. Moreover, with the adapters help, they can be used to terminate links on the cassettes in the fiber patch panels.

Forthwith, if we talk about their appearance, with the naked eye, if you see, there is very little difference between MTP and MPO connectors. Both the MPO and MTP can get connected with the 12/24/48/72 fiber connector, have the key on one side, and have male and female plug types as well. However, even though they both are compatible, there is a significant and concrete difference between MPO and MTP as the design of the connectors are different.

Features & Benefits Of MTP

- Less Time & Less Space For Deployment

Before the MTPs existence, it took an entire day to install and check 110-120 cables. However, as the MTP came into the market, cutting the days’ time into just a few hours, the installers installed 8 to 12 fibers in one time, with very few tools, and a complete deployment took just a few hours. After the MTP came into being, to architect the cabling structure became really simplified. As MTP has been a solution to the cabling of the entire industry, this became the standard of the industry too.

- Simplified Installation

The MTP connector has one ferrule that has multiple fibers.

If we compare the installation time of the MTP and other traditional fiber systems, then the time MTP takes is 75% less than any other.

Then, coming to the housing, the MTP has removable housing, which allows the re-working and re-polishing of the MT ferrule. With that, the quick transmission of the gender from female to male and vice versa can instantly be achieved, too. As it is removable, so in order to change the gender, all you have to do is, take out the connector, clean it, and plugin back to return it to the service. The removable housing is always an easy and effective solution for the users.

- Stability

In the year 2002, US conec, seeing the demand for the high performance, resettled MTP’s original thermosetting ferrule technology to polyphenylene sulfide (PPS) thermoplastic injection moulding. Now, this thermoplastic is less sensitive to moisture and is more resilient to varying temperatures. This less sensitivity meets the high volume demand of the stable connections and improves the performance of the connectors too.

Also, there is the metal pin clamp in the MTP connectors, which helps eliminate the lost pins and center spring force. So, the spring design enhances the clearance of ribbon for multi-fiber ribbon application, which prevents damage to the fiber. If we talk about the overall performance and the stability, the MTP for any data center or to be installed at any place is the best choice.

- Flexibility

The MTP connector has four standard variations of strain relief boots that give more flexibility over the cable that is used. The short boot design always reduces the footprint by 45% and makes the application of the same ideal for the places where there is limited space. Also, to utilize the cables in the short space, the strain relief boots enable the cables to get stretched from 0 to 90 degrees. When the stretch is this much, then managing the cables gets easier in the small space.

However, as flexibility is higher, the MTP provides stability. It is very easy to install, takes less space and fewer skills for the installation, and has become the industrys standard. However, as there were demands from some kinds of industries for the higher-performance connector, to satisfy those demands, the MTP Elite connector was made.

MTP Elite Connectors:

The MTP elite connectors are the ‘Lower Loss and Higher Performance Connectors.’ As the demand kept increasing for the higher performance, and it emerged that there was the need for a more stable network, higher-speed, and higher-performance, the MTP evolved to the MTP elite connectors. The MTP elite is the superior version of the MTP connectors, as the MTP was the higher-performance version of MPO. After all, the technology always has to develop! These connectors are manufactured to be more precise and of higher-quality standard. As MTP elite are made for higher performance, what basically in them has changed is, they have very less Optical Return Loss than that of the MPO and MTP. Thus they have a more stable, reliable, and high-density network.

Some MTP Related FAQs

What Is MT Ferrule?

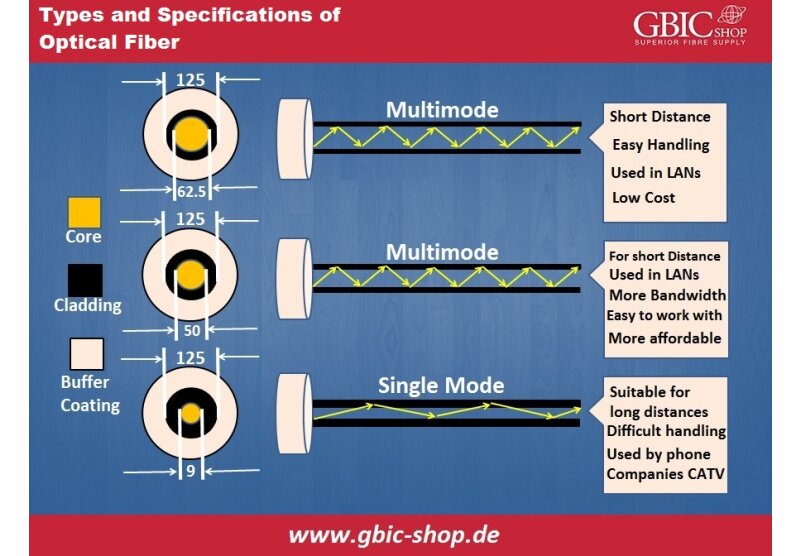

For mechanically transferable, the abbreviation MT is used. The MT ferrule is a plastic ferrule made of multi-fiber that has a square end face of 6.4x2.5 mm and a fiber pitch of 0.25 mm that is used in the general fiber connectors.

Unlike other connectors, the ferrule used in the MPO and MTP is made of a monolithic, high precision glass-filled polymer and not a ceramic material. This is a material that is higher in quality and has high-density technology as well to achieve a low loss in each of the fibers.

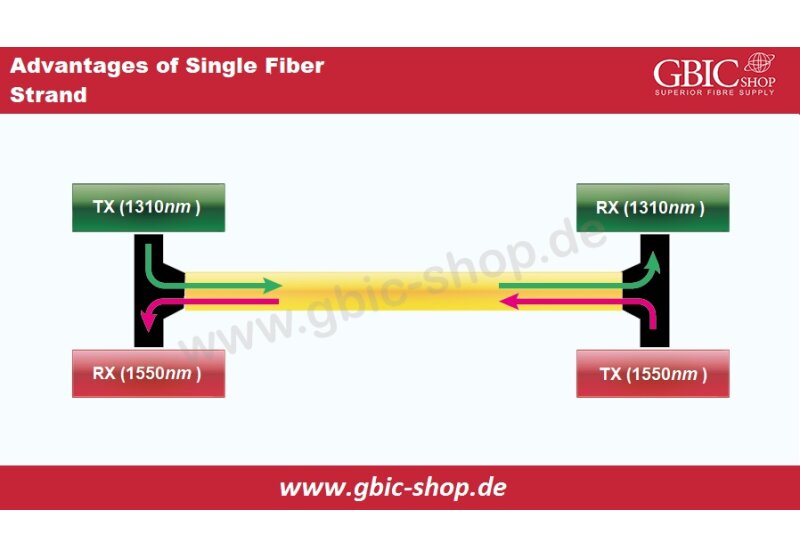

What Is Polarity?

The polarity is one of the main issues of the high-density MTP cabling system. Polarity describes if the transmitter at one end of the cable righty matches a receiver at the other end of the same or not. To keep the transmission process normal, the connector should be connected with the right polarity.

How To Maintain The Polarity?

Well, in the MTP system, the gender that is (male/female), the keys that are (KeyUp/KepUp, or KeyUp/KeyDown) and the alignment of end face that is (straight/angles) will all impact the polarity of the MTP. So, to keep it configured, as there are three polarity types, Type A, Type B, and Types C, the connection between them all must be aligned well to make the right transmission.

How To Clean MTP Connectors?

Cleaning the MTP connector is necessary while manufacturing and using it as well. So, the cleaning process of the MTP goes through three stages. Inspection, cleaning, and reinspection again.

While cleaning the connectors, after you have cleaned both the connectors, you need to inspect the same again with the microscopes help. Because if there is dust even in one, it can migrate to the other one as well. Also, if there is any particle of dust, the transmission will be affected. Alongside, it would be best if you clean the MTP connectors only with the help of MTP cleaning tools.

Espaniol

Espaniol

Deutsch

Deutsch

English

English