Today, Optical fiber has replaced metal wires in high-speed communication. An optical fiber is a single hair width fine filament drawn from molten silica glass.

Students often ask how fiber is made is as it’s not obvious how something only 1/8 of an mm - 0.005 inches in diameter can be made with such precision. In this article, we will discuss some basic facts about how optical fiber is manufactured. This may provide a better understanding of how optical fiber works.

At the Core

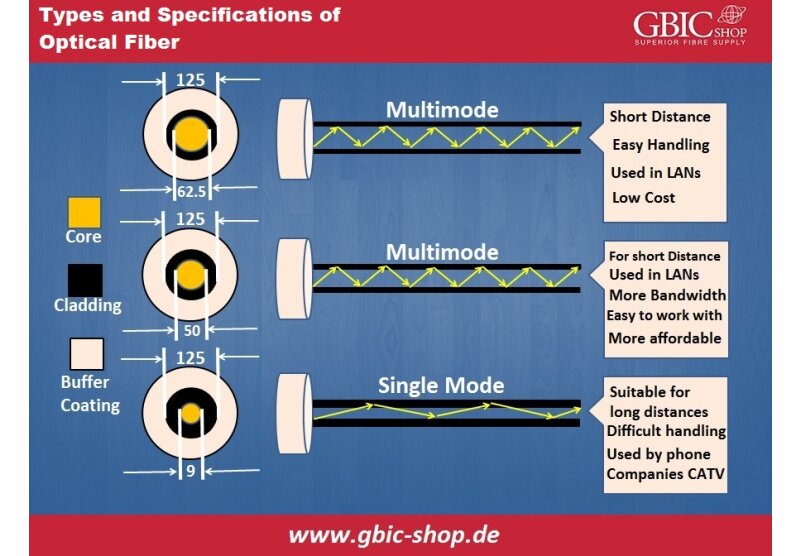

We have studied in the last article that there are two main types of optical fiber: Singlemode and Multimode. Both have two basic concentric glass structures:

the core and cladding.

Singlemode fiber has a smaller core of 9 microns in diameter and only 6 times the wavelength of light it transmits. This small size of the core limits the transmitted light in the fiber to only one principle mode. This minimizes dispersion of light pulses and increases the distance of the signal sent.

Multimode fiber has a large core diameter of 50 or 62.5 microns as compared to the wavelength. So, it propagates more than one mode of light. Therefore, Multimode fiber suffers more dispersion than single mode.

There are two main steps in the process of converting raw materials into optical fiber ready for transmission.

1. Manufacturing the Preform

The first step is to make a solid glass rod, which is known as preform. In this process, ultra-pure chemicals, primarily silicon tetrachloride (SiCl4) and germanium tetrachloride (GeCl4) are converted into glass. These chemicals are helpful in varying proportions to fabricate the core regions for different types of preforms.

Basic chemical reaction is:

- SiCl4 (gas) + O2 > SiO2 (solid) + 2Cl2 ( in heat)

- GeCl4 (gas) + O2 > GeO2 (solid) + 2Cl2 (in heat)

The core composition of all standard fibers consists of silica, with varying amounts of germania added to increase the fiber's refractive index. Single-mode fibers typically have only small amounts of germania and have a uniform composition within the core. Multimode fibers have a much higher refractive index and therefore have much higher germania content.

There are several other methods to manufacture preforms. One is the MCVD (Modified Chemical Vapor Deposition) process. In this highly controlled mixture of chemicals written above is passed through the inside of a rotating glass tube made of pure synthetic SiO2. The gas vapors are then conducted to the inside of a synthetic silica or quartz tube in a special lathe machine.

2. Drawing Fibers from Preform Blank

After testing the preform blank, it gets loaded into a fiber drawing tower to convert it into a hair-thin fiber.

The tip of the preform gets lowered into a graphite furnace at (1900 to 2200 degree Celsius) and the tip gets melted until a molten glob falls down by gravity. It then cools and forms a thread.

The threads are then stranded through a series of coating cups (buffer coating) and ultraviolet light curing ovens onto a tractor belt situated at the bottom of the draw tower and wound on winding drums. A laser micrometer is used to measure the diameter of the fiber and information is fed back to the tractor mechanism.

Fibers are pulled from the blank at the rate of 33 to 66 ft/s (10 to 20 m/s). Spools contain more than 1.4 miles (2.2 km) of an optical fiber.

3. Testing the Finished Optical Fiber

The finished optical fiber is tested for the following factors

Tensile Strength – It must withstand 100,000 lb/in2 or even more.

Refractive Index Profile – Determine numerical aperture and optical defects.

Fiber geometry – Verify that core diameter, cladding dimensions, and coating diameter are uniform.

Attenuation – Determine the extent when signal strength decrease over distance.

The information carrying capacity – Number of signals that can be carried at one time (multi-mode fibers)

Chromatic Dispersion/Operating Temperature/Humidity Range/Ability to conduct light underwater

Finally, the tested fiber is ready to be sold to telephone companies, cable companies and, network providers.

Espaniol

Espaniol

Deutsch

Deutsch

English

English