Fiber Optics Technology has been around since the 1960s and it has been developed further to meet the needs of our evolving technology. Many of the components of the Fiber optic system has also been developed since then, to satisfy the requirements of a better optical network.

Fiber Optic technology use pulses of light to transmit data into optical fiber cables, therefore it is very important to have a component at the end of these fibers to precisely propagate the transmitted light to its destination. Fiber Optics connectors are removable device utilized primarily to achieve a precise, accurate and stable connection at the end of the fiber. Moreover, these connectors are used to minimize the insertion loss of the transmitted power to achieve a better performance of the system.

Most of these connectors are made with high quality ceramic components or composite plastics to satisfy a reliable connection between fiber optic networks. While there are different kinds of optical connectors, these types are common in terms of their major components: the ferule, the connector body, the cable, the coupler or coupling mechanism, the stress relief boot and the Dust Cap. Here below, are some definitions:

-

Ferrule – A thin cylindrical component that is usually made from ceramic or high quality plastic. It is used to hold the glass fiber. Generally, hold one strand of fiber in its center and the end of it, is also the end of the fiber.

- Connector Body- It is the structure that holds the ferrule, primarily made of plastic or metal. It is a housing that supports the fiber cable.

-

Coupling Mechanism - A part of the connector body that provides the mechanism to keep the connector intact when attached into equipment, couplers or ODF (Optical Distribution Frames). It may be a latch type, snap-in, a nut or screwed-on.

- The cable – It is used to strengthen and support the fiber from mechanical and physical handling. It is attached at the connector body by crimping.

-

Stress Relief boot –Primarily made of soft plastic to protect the cable from stress and mechanical damage. Located at the joint of the cable and connector body and act as a jacket for protection.

- Dust Cap – A plastic cover to protect the ferrule and the fiber strand from any contamination (dust, dirt, oil, etc.), comes out of the box and usually at the end of the connector.

Fiber Optic Connectors must also comply with TIA/EIA, Telcordia, ICEA and other governing bodies for their basic physical, mechanical and optical performance standards as well as to conform with environmental standards. Furthermore, connectors must satisfy the acceptable standards in a fiber optic system like Insertion Loss, Return Loss, Connector Repeatability, Tensile strength and Temperature Tolerance.

FIBER OPTIC CONNECTOR TYPES

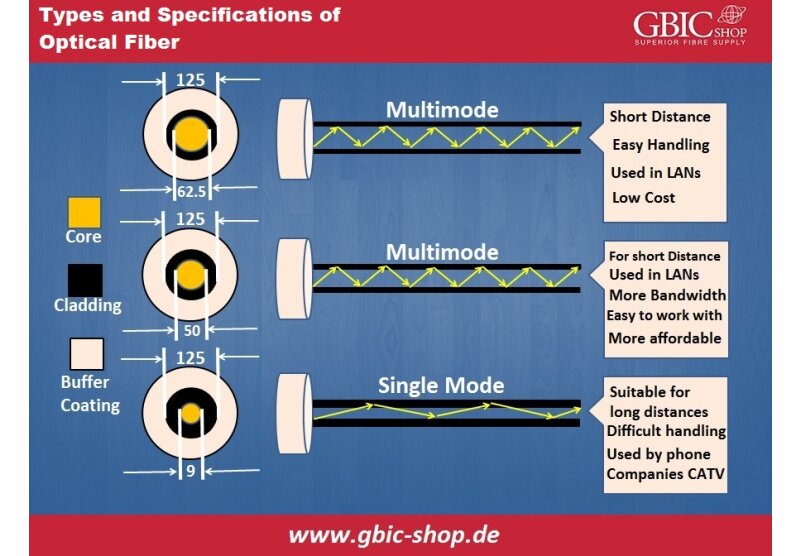

Most optical fibers connector comes in two design characteristics, either simplex which means one connector per end or duplex - two connectors per end. In addition, they are also based on different fiber optic transmission requirement, either in Multi-mode or in Single-Mode fiber configuration. These connectors can also be classified according to their structures, pin and surface configurations and number of fiber cores. Below are types of connectors that are accepted and widely used in the industry.

-

SC (Subscriber Connector)– This optical connector was one of the first optical connector in the market and was developed in Japan by a Japanese telecommunication company, NTT in the mid-eighties. It is used in either simplex or duplex and available in single mode or multi-mode. The connector body is square in shape and uses a circular pin type 2.5mm ferrule. This is a low- priced connector that has a snap-in/push-pull mechanism designed for quick and easy patching directly to an equipment or wall mounts. SC connectors have a mating cycles of 1000 and was standardized in Telecommunication Specification TIA-568-A.

-

LC (Lucent Connector)– One of widely used connector that was developed by Lucent Technologies, hence its name. It is commonly used in a duplex single mode fiber. This is considered as a Small Form Factor connector due to its small size. It uses a 1.25mm pin type ferrule and the connector itself resembles the RJ45 connector. It features a convenient push-and-latch mechanism that is very reliable patching to a rack mounted equipment. The combination of its small size and latch feature makes it excellent in a densely populated ODF or patch panel. It has a mating cycle of 1000 and is standardized in TIA/EIA-604.

-

FC (Field Assembly Connector) – The FC was the first optical connector to use ferrule thus it is sometimes called Ferrule Connector. It was invented in the Laboratory of NTT. Typically used for simplex single mode fiber. It is also a circular connector made from nickel-planted stainless steel and utilizes a 2.5 pin type ferrule. It has a screw-on treaded collet that is ideal at ODF on a high vibration environment. With a mating cycle of 1000 and is standardized in IEC 61754-13.

-

ST (Straight Tip) – Developed by AT&T after the invention of FC and one of the first and most popular connector that has been used. Widely used in a simplex configuration in multitude fibers. It has a circular with a combination of stainless metal and plastic body with a long 2.5mm pin type ferrule. It is a bayonet type of connector with a twisting mechanism and has a mating cycle of 500, standardized in IEC 61754-2.

-

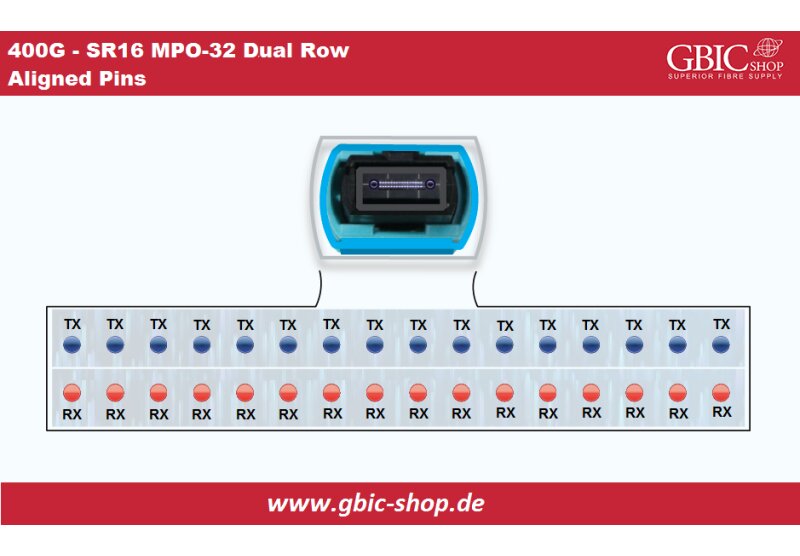

MPO/ MTP (Multi-fiber Push On) – This type of connector was also invented by NTT in the 1980s. It is commonly used as multi-fiber configuration available in 4,8,12 and 24 fiber cores, thus, it is larger than any connectors because it can hold up to 24 cores in a single ferrule. The cable of this connector is flat and requires mating to an opposing male or female connector. Standardized in IEC-61754-7.

-

MT-RJ (Mechanical-Transfer Registered Jack) – Developed by AMP/Tyco and Corning, is another Small Form Factor Connector. It is always in a duplex configuration, in single-mode or multi-mode fiber. Made of composite plastic, its body is designed for easier connection and disconnection like a small RJ45. It has two small 2.45 x 4.4mm fiber ferrule with guide pins for mating but it was designed with a male-female polarity. It has a mating cycle of 1000 and standardized in IEC 61754-18.

- MU (Miniature Unit) – MU is a Small Form Factor connector that was developed by NTT, sometimes called mini-SC. It has a plastic body and in simplex or duplex configuration. Its housing is designed for snap-in-push-pull mechanism suitable for backplane connection because of its retentive mechanism. With a ferrule of 1.25mm it has mating cycle of 1000 and standardized in IEC 61754-6.

Below are the summarized specifications of the mentioned fiber optic connectors:

|

Connector Type |

Housing |

Ferrule Size |

Coupling Type |

Fiber Confi- |

Fiber Type |

Insertion Loss |

Polish |

Mating Cycle |

Operating Temperature |

|

SC |

Plastic |

2.5mm, plastic |

Snap-in/ push-pull |

Simplex, Duplex |

SM, MM |

0.2-0.45dB |

PC, UPC, APC |

1000 |

-40 to +80 degrees Celsius |

|

LC |

Plastic |

1.25mm, ceramic |

Push and Latch RJ45 Style |

Simplex, Duplex |

SM, MM |

0.15dB(SM) 0.10dB(MM)

|

PC, UPC, APC |

1000 |

-40 to 75 degrees Celsius |

|

FC |

Metal |

2.5mm, ceramic |

Screw on |

Simplex, Duplex |

SM, MM |

0.5-1.0 dB |

PC, UPC, APC |

1000 |

-40 to +80 Degrees Celsius |

|

ST |

Metal |

2.5mm, ceramic |

Twist on |

Simplex, Duplex |

SM, MM |

0.40dB(SM) 0.50dB(MM) |

PC, UPC |

500 |

-40 to +80 degrees Celsius |

|

MPO / MTP |

Plastic |

2.5x6.4mm plastic |

Snap-in / Push-Pull |

Multi-fiber 4,8,12,24 fiber configuration |

SM, MM |

0.30 dB |

N/A |

500 |

-40 to +85 degrees Celsius |

|

MT-RJ |

Plastic |

2.5x4.4mm , plastic |

Snap-on RJ45 Style |

Duplex |

SM, MM |

0.30 dB |

N/A |

1000 |

-40 to +85 degrees Celsius |

|

MU |

Plastic |

1.25mm, ceramic |

Push-Pull |

Simplex, Duplex |

SM, MM |

0.30 dB |

PC, UPC, APC |

1000 |

-25 to +75 degrees Celsius |

Espaniol

Espaniol

Deutsch

Deutsch

English

English